UAE Marine & Offshore Excellence: Mingtai 5083 H111 Shipbuilding Aluminum Plates

Powering UAE’s ambitious maritime infrastructure and booming offshore sector demands materials that excel in strength, corrosion resistance, and unwavering reliability. Mingtai Aluminum, a leading global manufacturer, supplies the UAE market with premium AA5083 H111 Aluminum Alloy Plates. Renowned for exceptional marine performance, superior weldability, and backed by major international classification society certifications (including CCS, BV, ABS, KR, LR), Mingtai 5083 H111 provides the robust foundation for building safer, longer-lasting, and more efficient vessels and offshore structures.

Why Choose Mingtai 5083 H111 Aluminum Plate for UAE Marine & Offshore Applications?

Unmatched Seawater Corrosion Resistance:

The harsh, high-salinity environment of the Arabian Gulf demands top-tier corrosion protection. 5083 alloy, with its high magnesium content (4.0-4.9%), delivers exceptional resistance to both marine atmospheres and seawater immersion, far outperforming steel and other aluminum alloys. Mingtai’s precisely controlled composition and uniform microstructure ensure long-term durability, significantly extending service life and reducing maintenance costs and safety risks for vessels and offshore assets.

Superior Strength & Toughness (H111 Temper):

*5083 alloy offers medium-to-high strength. The H111 temper (strain-hardened and partially anneached) provides an optimal balance:

*High Load-Bearing Capacity: Withstands demanding conditions like wave impact, cargo loads, and structural stresses.

*Excellent Low-Temperature Toughness: Maintains critical impact resistance even in cryogenic environments (e.g., LNG carrier secondary barriers), ensuring structural integrity.

*Good Formability: Suitable for cold bending and rolling, essential for shaping hull plates and complex structural components.

Outstanding Weldability & Structural Integrity:

Shipbuilding relies heavily on welding. 5083 alloy boasts excellent weldability. Using standard MIG or TIG methods produces high-strength, ductile, corrosion-resistant welds. Mingtai’s high-purity plates with strict impurity control ensure weld joint properties match the base metal, guaranteeing the safety and longevity of the entire hull structure.

Major Classification Society Certified, Globally Accepted:

Mingtai 5083 H111 Marine Plates hold prestigious certifications from the world’s leading classification societies:

*China Classification Society (CCS)

*Bureau Veritas (BV)

*American Bureau of Shipping (ABS)

*Korean Register of Shipping (KR)

*Lloyd’s Register (LR)

These certifications are concrete proof of compliance with international shipbuilding codes and safety standards, providing strong validation for your projects to meet UAE and global maritime regulatory requirements.

Mingtai Aluminum: Your Trusted UAE Marine Plate Strategic Supplier

Choosing Mingtai means partnering with a source factory for professional expertise and worry-free assurance:

*Comprehensive Certifications, Guaranteed Quality: Products strictly adhere to international standards (ASTM B928, EN 485) and hold valid CCS, BV, ABS, KR, LR certificates. Every shipment includes a detailed Mill Test Certificate (MTC), guaranteeing compliance for chemical composition, mechanical properties (Tensile Strength ≥ 270 MPa, Yield Strength Rp0.2 ≥ 125 MPa, Elongation ≥ 12%), and process performance.

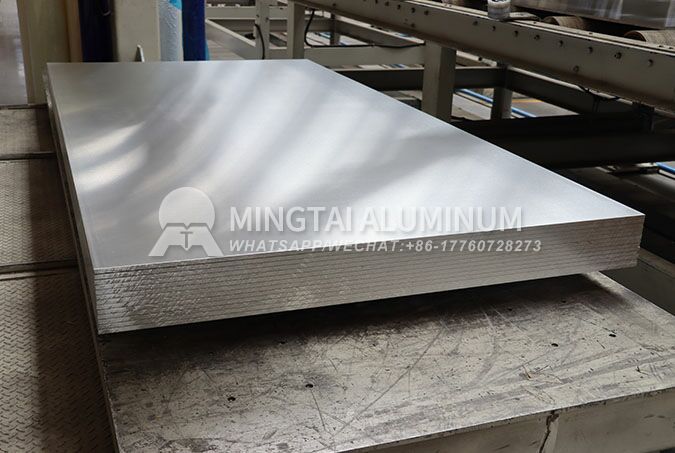

*Strong Capacity, Reliable Supply: Leveraging advanced hot continuous rolling lines and state-of-the-art equipment, we ensure stable, on-time delivery for UAE orders, supporting large-scale shipbuilding and offshore project timelines.

*Complete Specifications, Stock Availability: Maintains extensive stock of 5083 H111 plates in common marine thicknesses (e.g., 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm+) and various widths/lengths, catering to hull plating, decks, bulkheads, superstructures, and more.

*Expert Marine Application Support: Provides specialized material selection advice and technical consulting services for marine and offshore projects, helping optimize design, reduce costs, and enhance performance.

*Efficient Delivery to UAE Ports: Offers optimized international logistics solutions for secure and timely shipment to major UAE ports (e.g., Jebel Ali).

Contact Mingtai Aluminum Today for Your Marine Plate Solution & Competitive Quote!

Email: sales@mingtai-al.com

Tel/WhatsApp/WeChat: +86-17760728273

Website: www.mingtaialuminum.com

Factory Address: No. 162, Jinbai Road, High and New Technology Development Zone, Zhengzhou City, Henan Province, China

Choose Mingtai Certified 5083 H111 Marine Plate – Engineered Resilience for UAE’s Maritime Ambitions. Conquer Harsh Seas, Ensure Structural Safety, Set Sail for Success!

FAQ: Common Questions About Purchasing 5083 Marine Aluminum Plate in the UAE

Q1: Which parts of a ship are 5083 H111 plates primarily used for?

A1: Due to their excellent corrosion resistance, weldability, and strength-toughness balance, 5083 H111 plates are widely used for:

* Hull Shell Plating

* Main Decks & Superstructures

* Bulkheads & Hatch Coamings

* Secondary Barriers in LNG Carriers

* Offshore Platform Modules

* Speedboat & Yacht Hulls/Decks

* Coastal Structures (e.g., Fender Systems)

Q2: What exactly does the H111 temper mean? What are its advantages for shipbuilding?

A2: H111 temper indicates the plate has been lightly strain-hardened (cold worked) and then partially annealed (stabilized). This temper offers:

* Higher Strength: Significantly stronger than the fully annealed O temper.

* Good Formability: Easier to cold bend and roll-form than fully hardened tempers like H32/H34, making it ideal for curved hull plates.

* Reduced Residual Stress: Partial annealing minimizes internal stresses from processing, lowering risks of distortion after fabrication and stress corrosion cracking (SCC), enhancing structural stability.

Q3: What details are included in Mingtai’s Classification Society Certificates (CCS/BV/ABS etc.)? How can I verify authenticity?

A3: Classification Society certificates (typically Type Approval or Works Approval) include:

* Approved product specification (Alloy, Temper, Thickness Range)

* Applicable Standard(s)

* Approved Manufacturing Process Scope

* Certificate Validity Period

* Classification Society stamp/seal and signatures.

The Mill Test Certificate (MTC) supplied with the shipment will clearly state compliance with the relevant society’s rules (e.g., ABS or BV). You can request a certificate copy from Mingtai. Authenticity can be verified using the certificate number in the respective society’s online database. Mingtai guarantees all certificates are valid and authentic.

Q4: Are there special requirements for 5083 plates used in LNG carrier structures?

A4: LNG carriers impose stringent requirements, especially for low-temperature performance. Key points include:

* Stringent Toughness Requirements: Mandatory Charpy V-Notch impact testing at cryogenic temperatures (typically -196°C / liquid nitrogen) meeting minimum absorbed energy and lateral expansion values specified by classification societies and design codes (e.g., IGC Code).

* Tighter Chemical Control: Stricter limits on impurities (e.g., Fe, Si) to ensure low-temperature toughness and weldability.

* Enhanced Testing: Increased frequency of low-temperature impact tests may be required.

Mingtai has the capability and experience to produce 5083 plate meeting these high demands. Please specify your exact application and required standards during inquiry.

Q5: What is the typical shipping time and cost for sea freight from China to main UAE ports (e.g., Jebel Ali)?

A5:

* Shipping Time: Sea freight typically takes 15-25 days, depending on the port of origin (e.g., Shanghai, Ningbo, Qingdao), shipping line, route, and destination port. Jebel Ali (the largest Middle East port) has frequent services, ensuring relatively reliable transit times. Mingtai sales will provide current estimated schedules based on your needs.

* Freight Cost: Costs depend on multiple factors: cargo volume/weight (plates are dense, often charged by weight), current market freight rates (FAK), bunker adjustment factor (BAF), origin/destination port charges, insurance, etc. Mingtai will provide a detailed quote based on CIF Jebel Ali Port or other agreed Incoterms.

Q6: What special considerations are needed when processing 5083 H111 plate (cutting, welding)?

A6:

* Cutting: Suitable methods include plasma, laser, waterjet, or saw cutting. Maintain clean cuts; avoid iron contamination (causes pitting). Remove burrs and dross post-cutting.

* Welding:

* Filler Wire: Use ER5183 or ER5356 for matching strength and corrosion resistance.

* Cleaning: CRITICAL. Remove all oil, oxide film, and moisture from plate weld zones and filler wire. Use dedicated stainless steel brushes.

* Preheat: Generally not required. Light preheat (≤ 65°C) may benefit thick sections or cold environments to reduce porosity risk.

* Heat Input Control: Avoid excessive heat input to prevent grain growth in the weld/HAZ, which degrades properties. Control interpass temperature for multi-pass welds.

* Shielding Gas: Use high-purity Argon (≥99.99%).

* Cold Working: H111 temper allows moderate cold forming. Intermediate annealing may be needed for severe deformation. Stress relieving (150-200°C) post-forming is possible. Mingtai can provide detailed processing guidelines upon request.