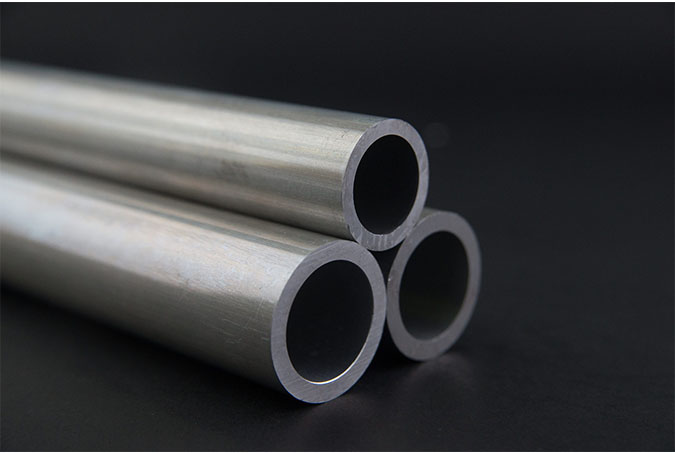

Seamless Aluminum Tube

Introduction

An extruded tube is brought to final dimensions by the hot extrusion process and can be seamless or non-seamless (structural tube). Compared to a slit tube(structural tube), an seamless aluminum tube/pipe is a tube that does not have any welding seam.

Our specialized process for seamless tubing manufacturing begins with either an extruded hollow tube or a solid bar drilled to our exact specifications. Mingtai seamless tubes are produced using two methods. One method pushes a hollow aluminum billet through a die and mandrel press with tremendous force at high temperatures. The other method pushes a solid billet through a piercer press and then a mandrel pierces and extrudes the billet in a second forward stroke. Regardless of the method used, the tube will have no weld or seam, making it ideal for anodizing and other finishing procedures.

What is Seamless Aluminium Tube/Pipe

An extruded tube is brought to final dimensions by the hot extrusion process and can be seamless or non-seamless (structural tube). Compared to a slit tube(structural tube), an seamless aluminum tube/pipe is a tube that does not have any welding seam.

Our specialized process for seamless tubing manufacturing begins with either an extruded hollow tube or a solid bar drilled to our exact specifications. Mingtai seamless tubes are produced using two methods. One method pushes a hollow aluminum billet through a die and mandrel press with tremendous force at high temperatures. The other method pushes a solid billet through a piercer press and then a mandrel pierces and extrudes the billet in a second forward stroke. Regardless of the method used, the tube will have no weld or seam, making it ideal for anodizing and other finishing procedures.

Specifications of Seamless Aluminum Tube/Pipe

| Products Name | Seamless Aluminum Tube/Pipe (extruded seamless tube and drawn seamless tube) |

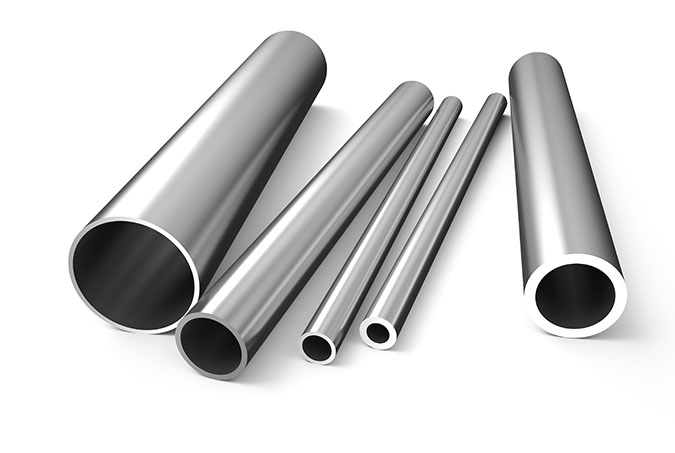

| Outer Diameter | 8~ Φ280mm |

| Wall Thickness | 0.1~ 20mm |

| Alloy Grade | 2011, 2024, 3003, 5052, 6061, 6063, 7075, etc. |

| Surface Treatment | 1) Mill finished 2) Anodizing: shiny anodized, frosty anodized 3) Electrophoretic coating: shiny electrophoretic, frosty electrophoretic 4) Electrophoretic color powder coating: normal color, special color 5) Fluorocarbon powder spraying: normal color, special paper 6) Polished |

Key Applications of Aluminium Pipes & Tubes Across Industries

Aluminum pipes and tubes have a wide range of applications across various industries. Some of the common applications of aluminium pipes and tubes are:

●Construction:Aluminium pipes and tubes are widely used in construction due to their lightweight, durability, and corrosion resistance properties. They are used in building structures, roofing, curtain walls, and other architectural applications.

●Automotive: Aluminium pipes and tubes are used in the automotive industry due to their lightweight and high strength properties. They are used in exhaust systems, engine cooling systems, and air conditioning systems.

●Aerospace:Aluminium pipes and tubes are used in the aerospace industry due to their lightweight and high strength properties. They are used in the construction of aircraft fuselages, wings, and other structural components.

●Electrical:Aluminium pipes and tubes are used in the electrical industry due to their good electrical conductivity and corrosion resistance properties. They are used in power transmission lines, bus bars, and other electrical applications.

●Marine:Aluminium pipes and tubes are used in the marine industry due to their corrosion resistance properties. They are used in the construction of boat and ship structures, as well as in marine equipment and fittings.

●Packaging:Aluminium pipes and tubes are used in the packaging industry due to their lightweight and corrosion resistance properties. They are used in the production of tubes for cosmetics, pharmaceuticals, and other products.

●Industrial:Aluminium pipes and tubes are used in various industrial applications such as heat exchangers, air conditioning systems, and fluid handling systems due to their lightweight, high strength, and corrosion resistance properties.

FAQs Of Seamless Aluminium Tube/Pipe

1. What is an aluminum tube used for?

Aluminum tubes and pipes have a high thermal conductivity, which makes them ideal for refrigerators, HVAC, and engine parts.

2. Is the aluminum tube easy to bend?

Aluminum alloy 6063 is a good choice, for example, while 6082 is more difficult. I would avoid using alloys in the 2xxx family because they are so strong and therefore difficult to form. However, in the right temper, the bending of those alloys is also possible.

3. Is aluminum tubing as strong as steel?

The tensile strength of standard structural steel can range from 400 MPA to 500 MPA (58,000 to 72,500 psi), while aluminum's is typically around 90 MPA (13,000 psi). This means steel can withstand significantly greater tension before failure than aluminum.

4. Is aluminum more expensive than steel?

However, it's essential to delve deeper and differentiate between specific types of steel. Mild and carbon steels typically come at a lower cost than aluminum, whereas stainless steel carries a higher price tag than aluminum.

5. What is the difference between an aluminium pipe and an aluminium tube?

The main difference lies in how they are measured. Aluminium pipes are typically round and measured by their internal diameter, making them suitable for transporting fluids and gases. Aluminium tubes can be round, square, or rectangular and are measured by their outer dimensions and wall thickness, making them ideal for structural and engineering applications.

6. What are the common applications of aluminium pipes and tubes?

Aluminium pipes and tubes are widely used in industries like construction, automotive, aerospace, marine, oil & gas, chemical processing, and power generation. They are also used in air systems, architectural frameworks, and equipment manufacturing because of their strength, lightweight, and corrosion resistance.

7. Which aluminium grades are commonly used for pipes and tubes?

Popular grades include Aluminium 6061, 6082, 5083, 7075, and 6063. Each grade has unique properties — for example, 6061 offers excellent corrosion resistance, 6082 provides high strength, 5083 is great for marine applications, and 7075 is preferred in aerospace and automotive due to its toughness.

8. What are the advantages of using aluminium pipes and tubes?

Aluminium pipes and tubes are lightweight yet strong, resistant to corrosion, durable in high-temperature environments, and easy to fabricate. They also have excellent thermal and electrical conductivity, making them suitable for a wide range of critical industrial applications.

9. Do you provide customised aluminium pipe and tube sizes?

Yes, Mingtai Aluminum offers custom aluminium pipes and tubes in various shapes (round, square, and rectangular), sizes, wall thicknesses, and finishes to match specific project requirements. We also provide testing and safe packaging for reliable delivery worldwide.