5086 Aluminum Alloy for Pressure Vessels | Marine-Grade H116 Plate | Mingtai Al

Engineered for Safety & Durability: 5086 Aluminum Alloy for Pressure Vessel Applications

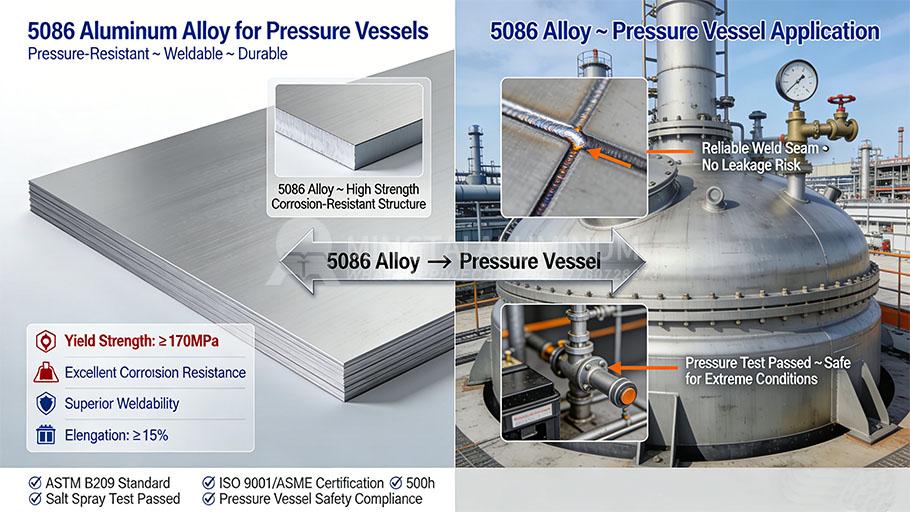

In the critical realm of pressure vessel design—from marine fuel tanks and offshore platform components to chemical processing equipment—material selection dictates safety, longevity, and operational reliability. For engineers specifying materials that must withstand internal pressure, harsh external environments, and cyclic loading, 5086 Aluminum Alloy emerges as a premier solution. Mingtai Aluminum (Stock: 601677), a specialist in high-performance marine and structural alloys, supplies 5086-H32 and 5086-H116 aluminum plate specifically engineered to meet the rigorous demands of pressure vessel fabrication, offering an optimal balance of strength, corrosion resistance, and weldability.

Why 5086 Alloy is the Standard for Demanding Pressure Vessels

Pressure vessels operate in some of the most punishing conditions. 5086 alloy, an Al-Mg alloy, is renowned for its exceptional combination of properties tailored for this role:

Superior Strength, Especially in Marine Environments: With a higher magnesium content than 5052 or 5454, 5086 aluminum provides a higher as-welded strength, making it ideal for welded structures under pressure. The H116/H321 tempers offer enhanced resistance to stress corrosion cracking, a critical factor for marine and coastal applications.

Outstanding Corrosion Resistance, Particularly to Seawater: This is 5086’s defining advantage. It exhibits excellent resistance to saltwater corrosion, outperforming many other aluminum alloys. This makes it the go-to choice for marine pressure vessels, shipboard tanks, and offshore applications where exposure is constant.

Excellent Weldability with High Joint Efficiency: 5086 can be readily welded using conventional methods (MIG/TIG) with appropriate 5XXX series fillers (like 5183 or 5356). It retains a high proportion of its base metal strength in the weld zone, ensuring the integrity of the pressure boundary.

Good Low-Temperature Performance: It maintains excellent toughness and ductility at cryogenic temperatures, suitable for applications like LNG transport or storage.

Technical Specifications for Pressure Vessel Design

Mingtai’s Pressure Vessel Grade 5086 Aluminum Plate is produced to exacting standards suitable for code construction (e.g., ASME BPVC).

Alloy: 5086 (AlMg4.5Mn0.7)

Preferred Tempers: H116 or H321 – These strain-hardened and stabilized tempers are specifically developed to provide superior resistance to exfoliation and stress corrosion cracking in marine atmospheres, which is paramount for pressure vessel safety.

Key Mechanical Properties (Typical, H116):

Tensile Strength: ≥ 290 MPa

Yield Strength (Rp0.2): ≥ 205 MPa

Elongation: ≥ 12%

Standards Compliance: Can be supplied to meet ASTM B209, EN 485, and other international specifications relevant to pressure equipment.

Available Forms: Plate in thicknesses commonly ranging from 6mm to 100mm+, tailored for vessel shells, heads, and reinforcements.

Critical Applications in Pressure Systems

Our 5086 aluminum plate is specified for demanding pressure-containing components across industries:

Marine & Offshore: Ship fuel and ballast tanks, LNG carrier secondary barriers, offshore platform pressure modules, and submarine air flasks.

Transportation: Road and rail tankers for chemicals, compressed gases, and liquids.

Energy & Chemical Processing: Heat exchangers, columns, and process vessels in mildly corrosive environments, especially where weight savings versus stainless steel is desired.

Cryogenic Vessels: Internal components and shells for systems handling liquefied gases.

Mingtai Aluminum: Your Partner for Critical Fabrication Materials

As a leading manufacturer of 5086 marine-grade aluminum plate, Mingtai understands the zero-failure tolerance of the pressure vessel industry.

Quality with Traceability: We provide full material certification (3.1 Mill Certificate) with traceable heat numbers, supporting your ASME U Stamp or other regulatory documentation.

Technical Expertise: Our metallurgical team can advise on temper selection (H32 vs. H116), welding procedures, and performance expectations for your specific service environment.

Precision Supply: We offer plate with guaranteed dimensional tolerances and can provide pre-machined or cut-to-size blanks to optimize your fabrication workflow.

Specify the Material Engineered for Pressure

When the integrity of your pressure system is non-negotiable, specify the alloy engineered to perform. Choose Mingtai’s 5086 Aluminum Alloy for your next pressure vessel project.

Contact our industrial and marine team for technical data sheets, certification details, and a competitive quotation.

Email: sales@mingtai-al.com

WhatsApp: +86-17760728273

Website: https://www.mingtaialuminum.com/