Mastering Formability & Strength: The Dual Advantages of 5754 H111 Aluminum

Mastering Formability & Strength: The Dual Advantages of 5754 H111 Aluminum

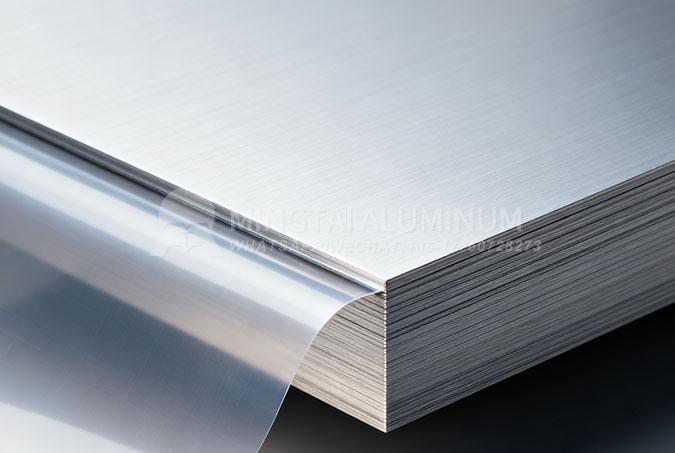

In the realm of engineering and manufacturing, the ideal material often strikes a perfect balance between opposing properties. For applications demanding complex shapes without sacrificing structural integrity, 5754 H111 Aluminum emerges as a premier choice. Mingtai Aluminum (Stock: 601677), a specialist in aluminum alloys, delves into the core properties of formability and strength that make 5754 H111 indispensable for transportation, vessel building, and industrial fabrication.

The H111 Temper: A State of Optimal Balance

The “H111” designation signifies a material that has been partially strain-hardened and then stabilized. This specific thermal-mechanical treatment places 5754 H111 in a unique position between the fully soft O-temper and the harder H32/H34 tempers, offering a synergistic blend of:

Enhanced Formability: Superior to fully hardened states.

Useful Strength: Significantly higher than the annealed condition.

Dimensional Stability: Resists age-softening or distortion after forming.

Property Deep Dive: Unmatched Formability

The excellent formability of 5754 H111 is its most celebrated feature, rooted in its mechanical profile.

Technical Basis: It possesses a relatively low yield strength coupled with a high elongation (typically ≥12-20%). This means the material yields and deforms plastically under stress long before fracturing.

Practical Fabrication Advantages:

Bending: Allows for tight bend radii (as low as 0.5 to 1 times the thickness) without cracking.

Stamping & Drawing: Excellent for moderate deep-drawing and forming complex contours, making it ideal for truck body panels, tank heads, and enclosures.

Roll Forming: Easily shaped into custom profiles through continuous roll-forming processes.

Comparison: Its formability is demonstrably superior to the stronger but less malleable 5754 H32, reducing spring-back and tool wear.

Property Deep Dive: Reliable Foundation Strength

While prized for formability, 5754 H111 provides a robust foundation of strength for numerous structural applications.

Typical Mechanical Properties (per ASTM/EN standards):

Tensile Strength (Rm): 180 – 250 MPa

Yield Strength (Rp0.2): 80 – 120 MPa

Elongation (A50): ≥ 12%

The “Work Hardening” Benefit: A key advantage is its response to cold working. During forming operations like bending or rolling, the deformed areas undergo “work hardening,” where their local strength and hardness increase significantly above the base material values. The final fabricated component is often stronger than the original sheet.

Weldability & Strength Retention: 5754 H111 welds beautifully (using 5356 filler). Crucially, the Heat-Affected Zone (HAZ) experiences less severe softening compared to heavily strain-hardened tempers. Post-welding, the structure can regain strength through natural aging or light cold working.

Applications Powered by This Balance

This combination directly translates into real-world performance:

Transportation: Complexly formed van and trailer side panels, cab components.

Pressure Vessels & Tanks: Formed dished ends and shells for containers.

Marine: Superstructure panels and interior fittings for boats.

General Engineering: Brackets, chassis parts, and machine guards requiring forming and welding.

Why Source 5754 H111 from Mingtai Aluminum?

Mingtai ensures precise control over the annealing and stabilization process to deliver 5754 H111 with consistent, predictable performance.

Certified Quality: Full material traceability and compliance with international standards.

Technical Support: Expert advice on forming limits and design optimization.

Processing Services: Precision slitting and cutting to reduce your fabrication time.

Unlock the potential of versatile fabrication with 5754 H111. Contact Mingtai for specifications, samples, or a quote.

Email: sales@mingtai-al.com

WhatsApp: +86-17760728273

Website: https://www.mingtaialuminum.com/