6101 aluminum alloy for the bus bar conductor for NEV and super charging piles

In the rapidly evolving new energy sector, efficient power transmission is critical for electric vehicles (EVs) and super charging piles. 6101 aluminum alloy, a high-performance material engineered for electrical conductivity and durability, has emerged as the preferred solution for bus bar conductors. Henan Mingtai Aluminum Co., Ltd. (Stock Code: 601677), a leading private aluminum processor in China, specializes in producing top-tier 6101 alloy products tailored for these applications.

Why 6101 Aluminum Alloy Excels for Bus Bar Conductors

Superior Electrical Conductivity

6101 aluminum alloy boasts an electrical conductivity of 55-61% IACS (International Annealed Copper Standard), making it a cost-effective alternative to copper while maintaining efficient power transmission. This minimizes energy loss during charging, enhancing overall system efficiency.

Lightweight and High Strength

With a density 1/3 that of copper, 6101 alloy significantly reduces the weight of bus bars, crucial for lightweighting EVs and charging infrastructure. Its T6-state heat treatment ensures a tensile strength of ≥205MPa, balancing durability and performance under high-current conditions.

Corrosion Resistance and Longevity

The alloy’s Al-Mg-Si composition provides exceptional resistance to corrosion, oxidation, and environmental degradation, ensuring reliable operation in humid or coastal environments.

Thermal Stability

Effective heat dissipation properties prevent overheating during rapid charging, extending the lifespan of both the bus bar and connected components.

Applications in New Energy Ecosystems

Electric Vehicle Battery Systems: 6101 bus bars connect battery modules, enabling efficient current flow while reducing vehicle weight.

Super Charging Piles: High-current transmission lines in DC fast chargers rely on 6101 alloy for safe, stable power delivery.

Renewable Energy Integration: Used in solar inverters and wind turbine converters for grid-connected systems.

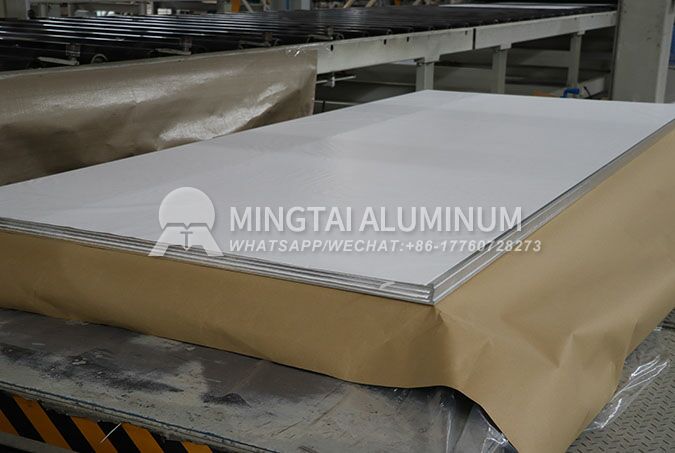

Mingtai Aluminum: Pioneering 6101 Alloy Innovation

Established in 1997 and listed on the Shanghai Stock Exchange, Mingtai Aluminum operates advanced production lines, including:

CVC6 Roller Cold Rolling Mills for precision thickness control.

“1+4” Hot Rolling Lines for large-scale alloy production.

Comprehensive recycling systems for sustainable aluminum utilization.

The company’s 6101 alloy products comply with AA (Aluminum Association) and GB/T standards, offering customizable thicknesses (0.5–500mm) and states (T4, T6, H112). With 6,000+ employees and 600+ technical experts, Mingtai ensures stringent quality control and rapid delivery.

Contact Mingtai Aluminum

For inquiries about 6101 aluminum alloy bus bars:

Email: sales@mingtai-al.com

WhatsApp/Wechat: +86-17760728273

Website: www.mingtaialuminum.com