8021 vs 1235 Battery Foil: Corrosion Resistance Showdown for Li-ion Cells

Introduction: The Critical Barrier Against a Corrosive World

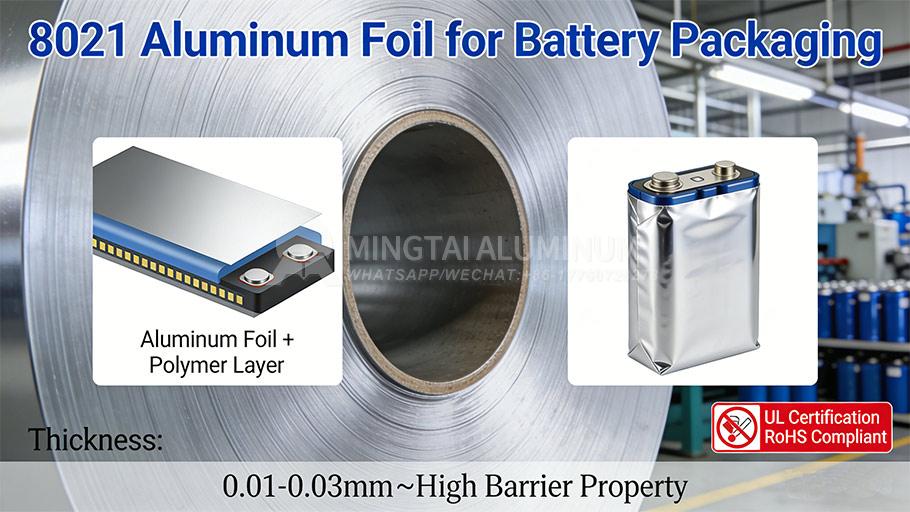

The selection of aluminum foil for lithium-ion pouch cells is a fundamental engineering decision that goes far beyond a simple “metal wrapper.” It forms the primary physical barrier against the highly reactive chemical environment within the battery. Faced with the two mainstream alloy choices—8021 and 1235—engineers and decision-makers often grapple with a pivotal question: Which material provides a more durable and reliable corrosion-resistant barrier for long-term battery performance and safety?

As a leading expert in high-performance aluminum foil manufacturing, Henan Mingtai Aluminum delves into a technical analysis of these two alloys under simulated battery conditions, empowering you to make a data-driven material choice.

Part 1: The Battlefield Inside a Pouch Cell

Within a pouch cell, the aluminum foil is in direct contact with the electrolyte, typically containing salts like LiPF₆ and organic solvents. Primary corrosion failure modes include:

●General Corrosion: Leading to overall foil thinning and reduced mechanical integrity.

●Pitting/Through-Porosity Corrosion: Localized penetration causing electrolyte leakage, gas generation, swelling, and eventual cell failure.

●Galvanic Corrosion: Particularly sensitive at areas with potential differences, such as tab welds.

The alloy’s composition design and microstructure are therefore the key determinants of its “corrosion armor” capability.

Part 2: Head-to-Head Technical Analysis: Composition & Inherent Properties

|

Property |

8021 Aluminum Alloy |

1235 Aluminum Alloy |

Impact on Battery Corrosion Resistance |

|

Core Composition |

Al-Fe-Si system, with trace Cu, Mn |

Pure Aluminum system (Al ≥ 99.35%) |

The alloying elements in 8021 form stable intermetallic phases, refining the grain structure and enhancing overall chemical stability. |

|

Common Temper |

H18, H19 (Hard) |

O, H18, etc. |

8021 is often supplied in hard tempers. While dislocation density is high, optimized annealing ensures no degradation in corrosion resistance. |

|

Tensile Strength |

Higher (Typ. ≥ 160 MPa) |

Lower |

Higher strength means 8021 better resists stress corrosion induced by cell cycling and expansion at identical thickness. |

|

Elongation |

Moderate (≥ 2%) |

Excellent |

While 1235’s purity offers superior formability, its lower strength can be a long-term liability under constant electrolyte exposure. |

|

Pinhole Control |

Excellent (Due to Fe addition, enhancing rolling uniformity) |

Good |

Fewer pinholes mean fewer initiation sites for corrosion. 8021 often demonstrates superior pinhole uniformity in ultra-thin gauges (e.g., ≤0.04mm). |

Part 3: The Decisive Test: Performance in Simulated Electrolyte Environments

Accelerated lab tests (e.g., salt spray, potentiostatic polarization) and real-world cell aging data indicate:

1. Long-Term Immersion Stability:

8021 Alloy: The finely dispersed secondary phases act as more effective barriers against corrosion channel propagation. This results in lower mass loss and shallower, more dispersed pitting.

1235 Alloy: As a high-purity aluminum, it is more prone to uniform corrosion. While it may perform adequately initially, under prolonged harsh conditions (high temperature, voltage), it may fail earlier due to overall thinning.

2. Interface Integrity:

Both alloys bond well with CPP/LMPP heat-seal layers. However, 8021’s superior strength provides a more stable substrate, reducing the risk of delamination caused by foil deformation during cell cycling. This indirectly protects the foil from localized attack.

3. Overall Battery Life Correlation:

Corrosion resistance is directly linked to cycle life and calendar life. Choosing 8021 alloy adds a layer of long-term reliability insurance, especially critical for Energy Storage Systems (ESS) and Electric Vehicle (EV) batteries targeting 10+ years of service.

Part 4: The Mingtai Advantage: Engineering Beyond Metallurgy

At Henan Mingtai, we understand that material is just the starting point. To unlock the full corrosion-resistant potential of our 8021 foil, we deliver an integrated “Alloy + Process” solution:

●Precision Composition Control: Ensures uniform element distribution and eliminates segregation weak points through strict ingredient ratios and melt purification.

●Optimized Annealing Technology: Our proprietary heat treatment profiles relieve internal stresses and stabilize the microstructure while maintaining high strength, effectively mitigating stress corrosion susceptibility.

●Surface Cleanliness Management: A cleanroom-like production process minimizes oil and dust contaminants—common catalysts for corrosion initiation.

●Customization & Testing: We offer simulation testing services tailored to your specific electrolyte chemistry and can adjust our process parameters for optimal compatibility.

Conclusion & Selection Guide: Choosing the Right Armor for Your Battery

|

Choose 8021 Aluminum Alloy if your priorities are: |

Consider 1235 Aluminum Alloy if your priorities are: |

|

✅ Superior Long-Term Corrosion Resistance & Maximum Reliability (e.g., for ESS, premium EVs) |

✅ Extreme Formability & Deep Draw Requirements (for certain niche cell designs) |

|

✅ High Strength to Resist Swelling (for large-format, high-energy-density cells) |

✅ Extreme Cost Sensitivity (for low-end consumer electronics batteries) |

|

✅ Pinhole Control for Ultra-Thin Foils (e.g., ≤ 0.04mm) |

✅ Projects where upfront cost outweighs long-term life. |

For the vast majority of lithium-ion battery projects prioritizing performance, safety, and total cost of ownership, 8021 aluminum alloy presents a more robust and future-proof choice, offering a superior balance of corrosion resistance, mechanical strength, and value.

Let Data Guide Your Decision: Request Your Comparative Analysis

Are you evaluating materials for a specific project? Henan Mingtai Aluminum can provide you with:

1.A detailed Technical Data Sheet (TDS) comparison between 8021 and 1235 alloys.

2.A proposal for customized corrosion testing against your electrolyte system.

3.Free foil samples for real-world cell prototyping and validation.

Contact our technical team today. Let Mingtai be your trusted partner in advanced battery material selection, helping you build safer, longer-lasting battery products.