Aluminum foil for lunch boxes 8011/3004/5052/8006 Aluminum foil multiple options

In the realm of food packaging, aluminum foil lunch boxes have emerged as a popular choice, thanks to their numerous advantages. When it comes to manufacturing these lunch boxes, the selection of the right aluminum foil alloy is crucial. Mingtai Aluminum offers a diverse range of aluminum foils, including 8011, 3004, 5052, and 8006, each with its own unique characteristics, catering to different requirements of the lunch box industry.

8011 Aluminum Foil: A Versatile Option for Lunch Boxes

8011 aluminum foil is a commonly used material in the production of lunch boxes. It belongs to the 8xxx series of aluminum alloys, with small amounts of iron (Fe) and silicon (Si) added to aluminum. This alloy combination endows 8011 aluminum foil with excellent formability. It can be easily stamped and shaped into various lunch box designs without cracking or deforming.

In terms of surface quality, 8011 aluminum foil produced by Mingtai Aluminum is top-notch. It has a clean and smooth surface, free from oil stains, inclusions, and pinholes. This not only ensures the aesthetic appearance of the lunch boxes but also meets strict hygiene standards. After passing multiple tests for bacteria and mold, 8011 aluminum foil from Mingtai Aluminum has been proven to be safe for direct contact with food.

The thickness of 8011 aluminum foil typically ranges from 0.01mm to 0.20mm, allowing for customization according to specific lunch box needs. Whether it’s a thin and lightweight design for single – use lunch boxes or a slightly thicker version for more durable, reusable ones, 8011 aluminum foil can fit the bill. Its good heat resistance enables lunch boxes to be used for both heating and cooling applications, from the freezer to the oven.

3004 Aluminum Foil: High – Strength Performance for Demanding Applications

3004 aluminum foil is another excellent option for lunch box manufacturing. As an alloy in the 3xxx series, it contains manganese (Mn) and magnesium (Mg) in addition to aluminum. The presence of these alloying elements significantly enhances its strength compared to some other aluminum foils.

For lunch boxes that require a higher level of structural integrity, such as those used for heavy – duty food storage or in industrial catering settings, 3004 aluminum foil is an ideal choice. It can withstand greater mechanical stress during the stamping process and maintain its shape even when subjected to rough handling.

Mingtai Aluminum’s 3004 aluminum foil is produced with advanced technology, resulting in a product with a flat and uniform thickness. The finished lunch boxes made from this foil have a consistent appearance, with no black oil spots, small black filaments, or bright lines that could affect the visual appeal or functionality. This high – quality 3004 aluminum foil is suitable for producing both standard – sized and larger, more complex – shaped lunch boxes.

5052 Aluminum Foil: Combining Corrosion Resistance and Good Workability

5052 aluminum foil, belonging to the 5xxx series, is known for its remarkable corrosion resistance. This makes it particularly suitable for lunch boxes that will come into contact with acidic or moisture – rich foods. The addition of magnesium as the main alloying element in 5052 aluminum foil forms a protective oxide layer on the surface, preventing corrosion and extending the lifespan of the lunch box.

In addition to its corrosion – resistant properties, 5052 aluminum foil also offers good workability. It can be easily processed into various shapes and sizes, making it a versatile option for lunch box manufacturers. Mingtai Aluminum’s 5052 aluminum foil has a smooth surface and excellent flatness, ensuring that the lunch boxes produced from it are free from defects such as wrinkles and uneven edges.

The thickness of 5052 aluminum foil available from Mingtai Aluminum ranges from 0.03mm to 0.2mm, providing flexibility in design. It is often used in the production of high – end lunch boxes, such as those for airline catering or premium food products, where both appearance and performance are of utmost importance.

8006 Aluminum Foil: Ideal for Achieving a Smooth and Wrinkle – Free Finish

8006 aluminum foil is a specialized alloy for lunch box production, especially for those aiming for a smooth and wrinkle – free finish. It is produced through a hot – rolling process, which results in a more uniform internal structure and better mechanical properties.

The tensile strength of 8006 aluminum foil from Mingtai Aluminum ranges from 123 – 135 MPa, providing sufficient strength for lunch box applications. After stamping, the edges of the lunch boxes made from 8006 aluminum foil are smooth and free from wrinkles, giving them an elegant and professional look. This makes 8006 aluminum foil highly suitable for high – end restaurants, hotels, and airlines that require aesthetically pleasing lunch packaging.

With a thickness range of 0.006mm to 0.2mm, 8006 aluminum foil can be customized to meet different design requirements. Its clean and oil – free surface, as produced by Mingtai Aluminum, further enhances its suitability for food contact applications, ensuring the safety and quality of the food stored in the lunch boxes.

Why Choose Mingtai Aluminum for Your Lunch Box Aluminum Foil Needs

Mingtai Aluminum, established in 1997, is a leading aluminum processing enterprise. With over 6000 employees and more than 600 professional and technical personnel, the company has the expertise and resources to produce high – quality aluminum foils.

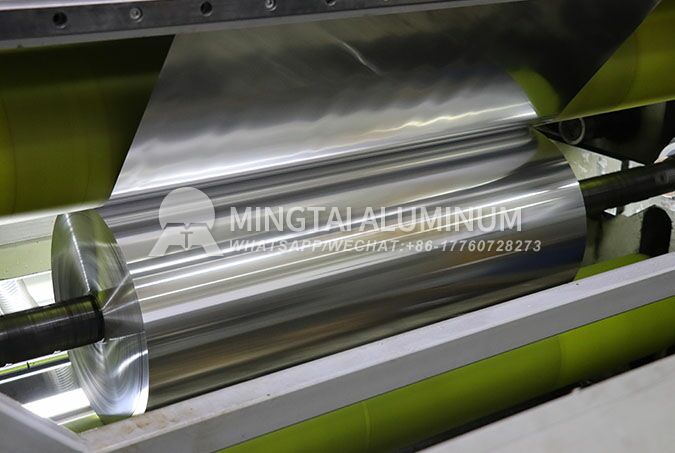

The company is equipped with a series of advanced production lines, including melting and casting lines, CVC6 – roller cold – rolling mills, annealing furnaces, and tension – bending straightening cleaning machines. These state – of – the – art facilities enable Mingtai Aluminum to strictly control the production process and ensure the consistent quality of its aluminum foils.

Whether you need 8011, 3004, 5052, or 8006 aluminum foil for your lunch box production, Mingtai Aluminum can provide customized solutions. The company offers a wide range of thicknesses and widths to meet your specific requirements. With a production capacity of 1300,000 tons of aluminum plates, strips, and foils per year, Mingtai Aluminum can also ensure timely delivery, with a delivery time of 3 – 25 days.

In terms of price, Mingtai Aluminum offers a competitive pricing model, with the product price calculated as “market aluminum ingot price + processing fee.” This transparency in pricing allows customers to have a clear understanding of the cost.

If you are interested in our lunch box aluminum foils or have any questions, please feel free to contact us. You can reach us via email at sales@mingtai-al.com or through Whatsapp/Wechat at +86 – 17760728273. For more information, visit our website at www.mingtaialuminum.com.

In conclusion, when it comes to choosing aluminum foil for lunch box production, the diverse options of 8011, 3004, 5052, and 8006 aluminum foils from Mingtai Aluminum provide you with the flexibility to meet different performance, design, and cost requirements. Trust Mingtai Aluminum for high – quality, reliable, and customized aluminum foil solutions for your lunch box manufacturing needs.